Theory and Application

MECS, opening up a new future.

What is Ultrasonic Soldering?

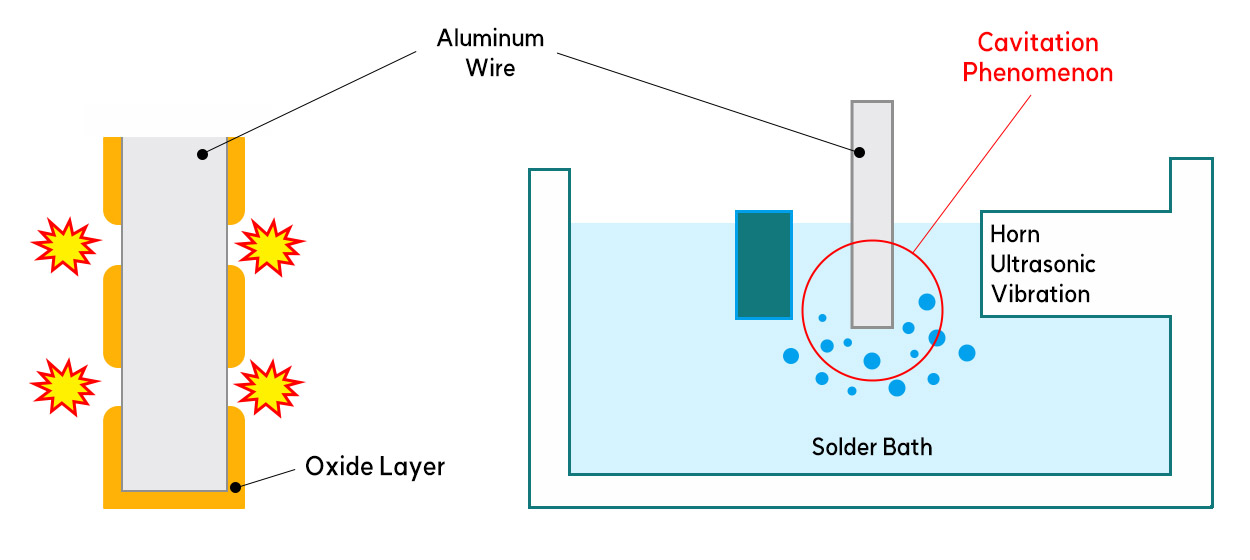

Ultrasonic soldering is the process of pretinning or metallizing the surface of almost any given material using an ultrasonic sonotrode instead of flux (Edison Welding Institute,USA) Ultrasonic soldering is a fluxless joining method in which high frequency mechanical vibrations replace the flux. The mechanical vibrations are transmitted to a liquid solder bath, and the energy of the mechanical vibrations causes cavitation to occur, thus eroding the surfaces of parts immersed in the bath. This removes the oxide layer on the surfaces of the parts and allows the melted solder to wet the clean metal surfaces.

Application of Ultrasonic Soldering

Motors

Fan Motor(for Microwave Oven)

Al wire (0.14mm) + Cu Terminal

Fan Motor(for Refrigerator)

Connection of Aluminum Wire and Copper Wire

Motor(for washing machine)

Connection of 6 pcs of Aluminum Wire and Copper wire

BLDC Motor(Refrigerator)

Connection of Aluminum Wire and Copper Terminal

Drain Pump Motor(Washing Machine)

Connection of Aluminum Wire and Copper Terminal

Transformer & Other Magnet Coil Product

Clutch Coil(Air conditioner of automobile)

Connection of Aluminum Wire and Copper terminal

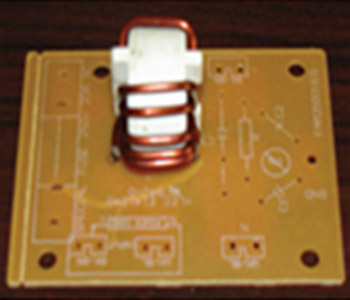

Noise Filter Coil

Connection of Aluminum Wire and PCB

Reactor(for Refrigerator)

Connection Aluminum Wire and Copper Terminal

Transformer(Forklift Battery Charger Transformer)

Coating plate-type Aluminum Wire with Tin(Sn) in order to prevent oxidization of aluminum wire after being clamped with Copper Terminal

Deflection York Coil(for CRT)

Connection of Aluminum Wire and Copper terminal

Electronic Components

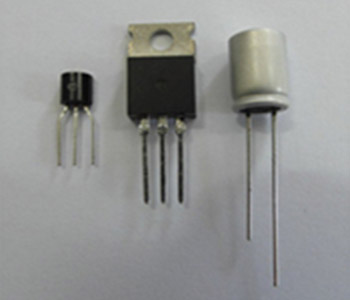

Soldering Electronic Component Lead

Utrasonic Soldering Iron’s Applications

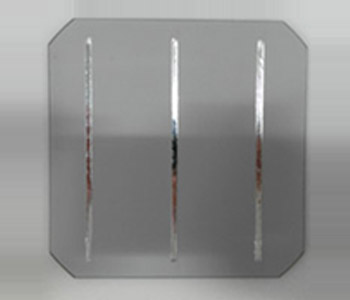

Solar Cell Soldering

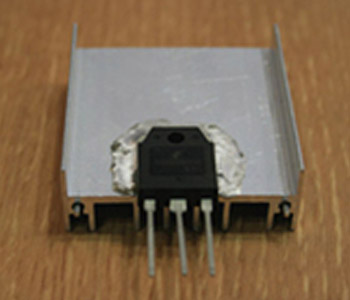

Soldering Aluminum Heat Sink & Transistor